Project

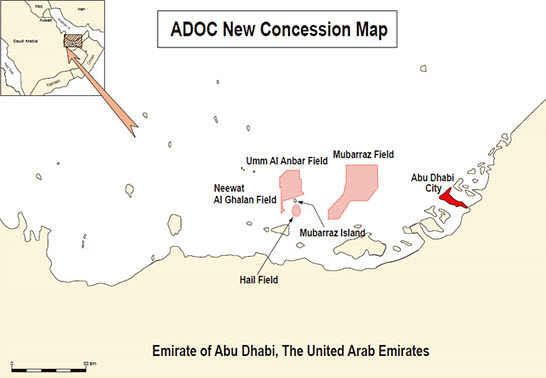

Location – Upper Zakum Ettouk Island and Umm Al Anbar Island

Client

–ADNOC Offshore

Main

Contractor – Venus Infrastructure Contracting

LLC

The Engineering, Procurement & Construction (EPC) project

scope included civil, mechanical, and electrical works to support new

accommodation facilities. Civil works involve the construction of essential

support buildings such as a kitchen, mess hall, recreation and laundry units,

along with the refurbishment and relocation of an existing G+2 camp. It also

includes demolition and removal of scrap materials to designated areas in Abu

Dhabi, as well as site preparation activities like clearing, underground utility

scanning, and topographic surveying. Mechanical works cover the installation of

HDPE potable water and UPVC sewer networks, booster pumps, and firefighting

systems with hydrants and hose reels. Electrical works include the supply,

installation, and commissioning of Diesel Generators, associated distribution

boards (Totalizing Panel, MDB, SMDBs), power and earthing cables, and fire

alarm systems with FACP and detectors.

Project Location – All Emirates in UAE

Client – ADNOC Distribution

Main Contractor – Venus Infrastructure Contracting LLC

The Engineering, Procurement & Construction (EPC) scope

consisted of civil and MEP works with excavation in the tank area and along

trenches to facilitate the replacement of fuel pipelines across 67 fuel

stations throughout all Emirates. This includes backfilling, compaction, and

reinstatement of surface features such as interlock paving and kerbstones,

along with the casting of spill containment structures. The Mechanical works

include the removal of the existing carbon steel fuel delivery pipeline and its

replacement with double-wall polyethylene piping from the fuel tank to the

dispenser. Additionally, the scope covers the supply and installation of

dispenser sumps and a flame arrestor equipped with a Pressure Vacuum Relief

Valve (PVRV) for the vent line.

Project

Location –Zakher Terminal Al Ain

Client

– ADNOC Distribution

Main

Contractor – Venus Infrastructure

Contracting LLC

The Engineering, Procurement & Construction (EPC) scope

of works included both mechanical and instrumentation activities. The

mechanical works involved the replacement of defective foam pumps at Al Ain

Zakher Terminal foam stations 01, 02, and 03, including necessary modifications

to upstream and downstream piping with stainless steel cladding. Additionally,

filtration and cleaning of existing foam tanks at all three pumping stations were

performed. The instrumentation works covered the supply and installation of

strainers, differential pressure gauges, pressure transducers, pressure relief

valves and pressure control valves, along with required modifications to the

associated piping.

Project Location - Umm Al Nar Abu Dhabi

Client – TRANSCO,

Main Contractor

– Venus Infrastructure

Contracting LLC

The Engineering, Procurement & Construction

(EPC) scope of works included comprehensive mechanical and instrumentation

activities focused on the supply and installation of electromagnetic flow

meters across key locations in the potable water distribution network,

specifically at Taweela A1, Taweela B2, Unit 3, Unit 4, and Umm Al Nar pumping

stations. These installations accommodated pipe sizes ranging from 600 mm to

1600 mm and involved all necessary shutdown operations to facilitate a safe and

efficient implementation. Additionally, the scope encompasses modifications to

the existing SCADA system to ensure proper integration of the new

instrumentation, enabling accurate real-time monitoring and control of the

water distribution system.

Project

Location – Abu Dhabi

Client

– ALDAR

Main

Contractor – Nurol LLC OPC

Scope of Works Includes

Civil & Electro-mechanical Works:

Mechanical Works: Supply and installation of

HDPE potable water networks with pipe sizes ranging from 80mm to 300mm,

including associated fittings such as tee valve chambers, flow meter and flow

control valve chambers, washout and air valve chambers, electromagnetic flow meters

within flow meter chambers, ductile iron pipes, accessories, and fire hydrants.

Electrical Works: Supply and installation of

sector measuring points, including GRP sector metering kiosks, along with all

associated cabling and earthing works.

Civil Works: Excavation, sand bedding, backfilling,

concrete encasement for road crossings, in-situ casting of valve chambers, pull

box chambers, and protection slabs.

Project

Location – Ruwais Port

Client

– Abu Dhabi Ports Group

Main

Contractor – Al Ryum Cont. & General Transport LLC

Scope of Works Includes

Electro-mechanical & Instrumentation Works

Electrical Works: Supply, installation,

testing, and commissioning of MCC panels, distribution boards, control panel

earthing systems, and associated cabling.

Instrumentation Works: Supply, installation,

testing, and commissioning of programmable logic controllers (PLCs), SCADA

workstations, electromagnetic flow meters, pressure transmitters, flood

detection systems, float switches, level transmitters, and instrumentation

cabling.

Mechanical Works: Supply, installation, testing, and

commissioning of submersible pumps, penstocks, macerators, ductile iron (DI)

pipes and fittings, valves, Jib cranes, and surge vessels.

Project

Location – Abu Dhabi

Client

– ALDAR

Main

Contractor – Nurol LLC OPC

The electro-mechanical works involved the supply and

installation of potable water and irrigation networks using ductile iron (DI)

pipes and fittings, with pipe sizes ranging from 80mm to 600mm. The scope

included the installation of valves, line valve chambers, tee valve chambers,

flow meter and flow control valve chambers, washout and air valve chambers, 14

electromagnetic flow meters housed within dedicated chambers, and 791 fire

hydrants. The electrical works comprise the supply and installation of sector

measuring points, including GRP sector metering kiosks, along with associated

cabling and earthing works

Project

Location – Al Ain

Client – Musanada /AADC

Main

Contractor – BATCO

The works consisted across storm water network and

pumping station included the installation of ductile iron (DI) pipes up to

DN500mm in size, along with valves and related accessories for the storm water

pumping station and associated external works. Electromechanical works

encompass pumps, MCC with automatic transfer switches (ATS), generators, flow

meters, valves, DI piping, and GRP piping systems. Electrical works involved

the installation of MCC panels, ATS units, generators, and associated cable

laying. Mechanical works cover the installation of DI pipes and fittings,

valves, flow meters, and pumps.

Project

Location – Madinat Zayed, Abu Dhabi

Client

– TRANSCO

Main

Contractor – METITO

The works consisted of fabrication and installation of

cast iron (CI) piping and pumping station works. For the potable water network,

the project involved fabrication, welding, and installation of carbon steel

piping for water distribution pipelines, along with equipment installation at

the pumping station. The work included carbon steel pipework up to 1600 mm in

diameter, a 100 m³ surge vessel, and horizontal split case pumps.

Project Location – Delma

Island

Client – Abu Dhabi Ports

Main Contractor - NMDC

The works consisted of

electrical and street lighting installations. This involved the supply and

installation of 14-meter-high light pole with single-arm LED luminaires,

complete with required foundations and accessories. Electrical works cover all

associated low-voltage (LV) cable networks from the substation, feeder pillars,

SLCC, and street light control cabinets, including solar timers and earth pits.

Project Location - Jubail

Island Abu Dhabi

Client – Jubail Island

Investment Company

Main Contractor - NMDC

The works consisted of electromechanical

and infrastructure utilities. For the potable water network, the project

involved supply, installation, testing, and tie-in of a DN225 main HDPE

pipeline, using butt fusion welding and horizontal directional drilling to

relocate the existing line. Works also included installation of ductile iron

fittings inside valve chambers, isolation gate valves, air release valves, and

removal of the existing HDPE pipeline. Electrical works covered the relocation

of the electrical network, including installation of uPVC cable ducts in

trenches and laying of 11 kV cables with joints and terminations.

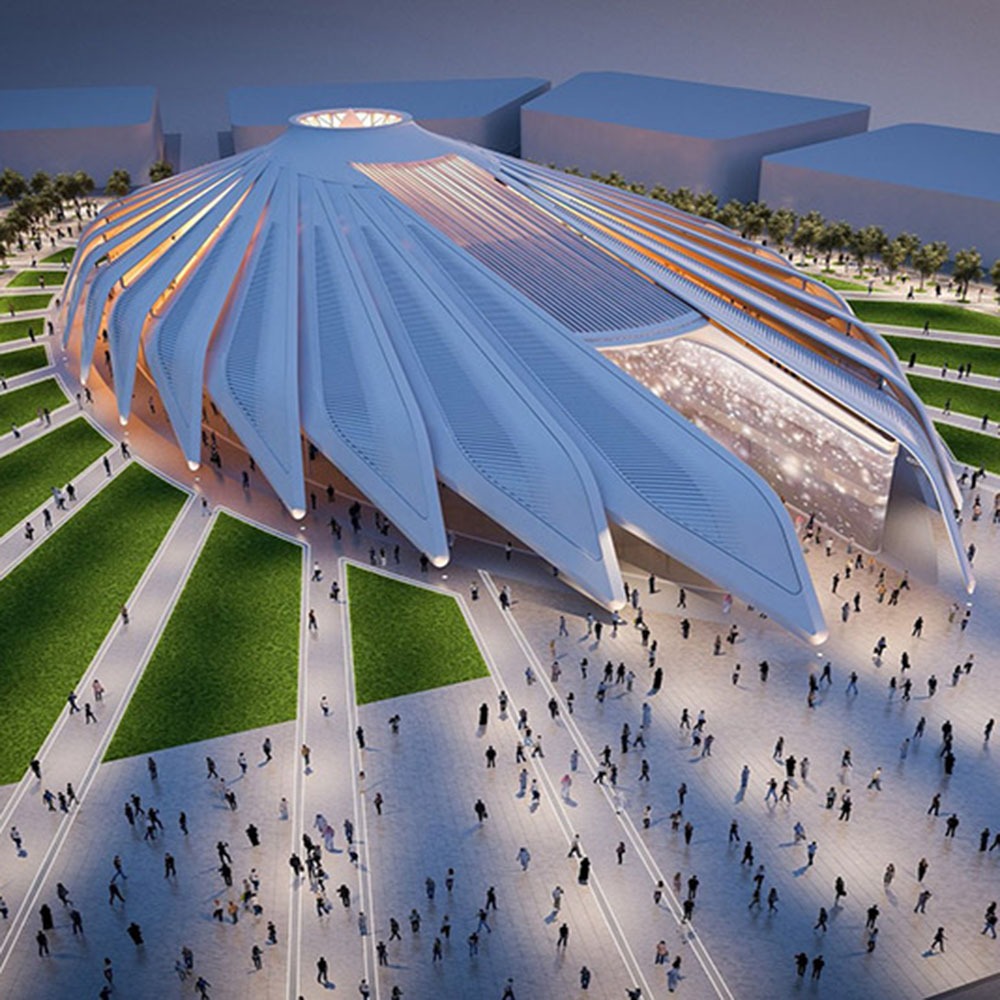

Project Location – Dubai

Client – EXPO 2020

Main Contractor

- Spacemaker

The works consisted of

electro-mechanical and utilities installations. For the Operations Pavilion,

MEP works involved the supply and installation of MDB, SMDB, FDB panels,

cables, lighting fixtures, switches, sockets, sanitary fittings, earth pits,

earth rods, and accessories for MDB, SMDB, capacitor banks, and the building

earthing system. The potable water system included supply and installation of

uPVC and PPR piping along with water meters. The drainage network covered the

supply and installation of uPVC drainage pipes and precast manholes.

Project Location – Fujairah

Client – Sharm Fujairah Real Estate

Main Contractor - BATCO

The works consisted of

comprehensive electro-mechanical and instrumentation works across potable

water, sewerage, and irrigation pumping stations. For the Potable Water Pump

Station, the scope covered installation of pumps (210 m³/hr at 6 bar), ductile

iron piping, valves, fittings, and a pressure vessel, along with electrical and

instrumentation works including distribution boards and cable laying. The Sewerage

Pumping Station involved installation of pumps (321 l/s at 18 m head), ductile

iron piping, valves, fittings, a lifting davit, macerator, and a 160 m³/hr

odour control unit, as well as MCC panels, distribution boards, and

instrumentation cabling. For the Irrigation Pumping Station, works included

installation of pumps (48 l/s at 40 m head), DI piping, valves, fittings, and a

1400 GPM irrigation filter, along with associated MCC panels and electrical

distribution systems.

Project Location - Fujairah

Client – Ministry of Infrastructure

Development

Main Contractor

- BATCO

The works consisted

of supply, installation, testing, and commissioning of storm water pumping

stations and associated mechanical, pipeline, and electrical works.

Storm Water Pumping

Stations: Installation of three pumping stations equipped with submersible

pumps—eight units with a capacity of 832.7 m³/hr and four units with a capacity

of 643 m³/hr. The scope also includes discharge pipeline works using GRP piping

(up to DN700), installation of penstocks (DN600, DN800), gate valves,

non-return valves (NRVs), and level instruments.

Sewerage Network: Installation

of GRP sewer pipes (up to DN700), manholes, and connection to existing sewer

manholes.

Electrical and

Electromechanical Works: Installation of systems for three substations,

including MCC panels, main distribution boards (MDs), capacitor banks, and

power cables ranging from 4C x 10mm² to 1C x 630mm². Additional works include

small power systems, air conditioning, NOVEC firefighting systems, and fire

alarm systems for the substation buildings.

Project Location - Saadiyat Island

Client – TDIC

Main Contractor - Nurol LLC

The project

encompasses the execution of comprehensive infrastructure utilities, including

irrigation, sewerage, pipeline relocation, and metering systems.

Irrigation Network: Supply,

installation, testing, and commissioning of HDPE pipelines (up to 630mm

diameter) using the open-cut method, and installation of a 630mm HDPE sea

crossing pipeline (700 meters) via Horizontal Directional Drilling (HDD), using

butt fusion welding. Electromechanical chamber works include Ductile Iron pipes

and fittings, gate valves, air release valves, flow meters, washout valves,

flow control valves, and accessories.

Pipeline Relocation: Supply,

installation, testing, and tie-in works for DN250 HDPE main pipeline using butt

fusion welding for the relocation of an existing line. Works include DI

fittings inside valve chambers, isolation gate valves, air release valves, and

removal of the existing pipeline.

Metering System: Supply

and installation of flow meters up to DN500 in size.

Sewerage Network: Installation

of a 315mm HDPE sewer force main using butt fusion welding and associated valve

chambers. Installation of GRP and uPVC gravity pipelines (up to DN1400 and

depths of up to 12 meters) between manholes, including tie-in works to the

existing STP plant using the Non-Disruptive Method (NDM) for DN1400 pipeline.

Client – Dubai Aviation

Engineering Projects Corporation

Project Location - Al

Maktoum International Airport

Main Contractor - Spacemaker

Dubai

The works consisted of

supply and installation of Form 2 SMDBs, along with the supply, installation,

testing and commissioning of Form 4b, Type-6 SMDBs. The works also covered

associated LV cable installations. Additionally, the scope includes the supply

and installation of a gate barrier system for parking management.

Project Location – Upper

Zakum Central Island

Client – ZADCO

Main Contractor

– Spacemaker

The works consisted of supply

and installation of a complete drainage network consisting of uPVC pipes and

fittings in accordance with BS EN 1401-1, with sizes up to 315mm, along with

precast concrete manholes. For the potable water network, the works involved

the supply and installation of uPVC pipes and fittings as per BS 3505

standards, up to 200mm in diameter, including the installation of pumps and a

pressure vessel. The electrical works covered the supply and installation of

Main Distribution Boards (MDBs), Sub Main Distribution Boards (SMDBs), as well

as associated power and earthing cable networks and the complete earthing

system.

Project Location – Upper

Zakum South Island

Client – ZADCO

Main Contractor

- Spacemaker

The works consisted of supply

and installation of uPVC pipes and fittings up to 315mm in diameter, along with

the installation of precast concrete manholes for the building’s external

drainage system. For the potable water network, the works involved supplying

and installing uPVC pipes and fittings (as per BS 3505) ranging from 50mm to

200mm in diameter, including pumps and a pressure vessel. Additionally, the

scope covers the supply and installation of a kitchen hood and chequered plates

as part of the kitchen modification works.

Project Location - Upper

Zakum West Island

Client – ZADCO

Main Contractor

– Spacemaker

The works consisted of

supply and installation of uPVC pipes and fittings for the drainage network, in

accordance with BS EN 1401-1, with pipe sizes up to 315mm, along with precast

concrete manholes. For the potable water network, the works involved the supply

and installation of uPVC pipes and fittings as per BS 3505 standards, with

sizes up to 200mm, including associated pumps and a pressure vessel. The

electrical works covered the supply and installation of Main Distribution

Boards (MDBs), Sub Main Distribution Boards (SMDBs), power and earthing

cabling, as well as the complete earthing system.

Project Location - Upper Zakum Central Island

Client – ZADCO

Main Contractor

- Spacemaker

The works consisted of

supply and installation of uPVC pipes and fittings for the drainage network,

complying with BS EN 1401-1 standards, with sizes up to 315mm, along with

precast concrete manholes. For the potable water network, uPVC pipes and

fittings are supplied and installed as per BS 3505 standards, with sizes up to

200mm, including pumps and a pressure vessel. The irrigation network involved

the supply and installation of uPVC pipes and fittings, also in accordance with

BS 3505, up to 200mm in size. Sewer lifting station works covered mechanical

and electrical installations, including pumps, valves, pipelines, and

low-voltage panels. Electrical works comprise the supply and installation of

Main Distribution Boards (MDBs), Sub Main Distribution Boards (SMDBs), power

and earthing cabling, and complete earthing systems.

Project Location - Upper

Zakum Central Island, West Island, South Island and North Island

Client – ZADCO

Main Contractor – Spacemaker

(Central, West & South Island) &

Leighton Contracting Abu Dhabi (North Island)

The scope of works comprised

comprehensive utility infrastructure installations. It included the drainage

network, involving the supply and installation of uPVC pipes and fittings (BSEN

1401-1, up to 315mm in diameter) and precast concrete manholes. For the potable

water network, the works cover the supply and installation of uPVC pipes and

fittings (BS3505, up to 200mm), along with the installation of pumps and a

pressure vessel. The irrigation network involves the supply and installation of

uPVC pipes and fittings (BS3505, up to 200mm). Additionally, sewer lifting

station works include the mechanical and electrical installation of pumps,

valves, pipelines, and LV panels. The electrical scope includes the supply and

installation of MDBs and SMDBs, as well as associated power and earthing

cabling works.

Project Location - Mafraq, Abu Dhabi

Client – SEHA

Main Contractor - Al Habtoor

Leighton Murray & Roberts

The Irrigation Feeder

Network scope included comprehensive electromechanical works for the irrigation

system. This involved the supply, installation, testing, and commissioning of

HDPE main pipelines (up to 400mm diameter), along with ductile iron (DI)

fittings, valves, and flow meters installed within valve chambers. The scope

also covered the installation of a control panel for the irrigation system, GRP

kiosks to house the flow meters, and all associated cable interconnections

required for system operation and monitoring.

Project Location - Hail

Island

Client – ADNOC

Main Contractor - NMDC

Abu Dhabi

The scope of works comprised

comprehensive utility infrastructure installations. It includes the drainage

network, involving the supply and installation of uPVC pipes and fittings (BSEN

1401-1, up to 315mm in diameter) and precast concrete manholes. For the potable

water network, the works cover the supply and installation of uPVC pipes and

fittings (BS3505, up to 200mm), along with the installation of pumps and a

pressure vessel. The irrigation network involves the supply and installation of

uPVC pipes and fittings (BS3505, up to 200mm). Additionally, sewer lifting

station works include the mechanical and electrical installation of pumps,

valves, pipelines, and LV panels. The electrical scope includes the supply and

installation of MDBs and SMDBs, as well as associated power and earthing

cabling works.

Project Location – Saadiyat Island, Abu Dhabi

Client – TDIC, Consultant

– CHSS

Main Contractor - NUROL

The Electromechanical

works comprise the complete scope for multiple systems. The Ventilation System

includes the supply, installation, testing, commissioning, and maintenance of a

Tunnel Ventilation System equipped with 20 Jet Fans, along with all required

cabling, control panels, and SCADA interface integration. The Drainage Network

with Pumping Stations covers the supply, installation, testing, commissioning,

and maintenance of storm water pumping stations, featuring 7 submersible pumps.

The Electrical Works

scope involves the supply and installation of control panels for both the

drainage and ventilation systems, including necessary cable laying and

terminations. The Mechanical Works include the supply, installation, testing,

commissioning, and maintenance of two storm water pumping stations, with

submersible pumps (7 Nos) and associated stainless steel piping (up to DN350)

complete with valves and non-return valves (NRVs).

Additionally,

Instrumentation and SCADA Interface Work involves the supply and installation

of ultrasonic level transmitters, float switches, and limit switches for

valves, with full integration of instruments into the SCADA system.

Project Location – Upper Zakum North Island

Client - NMDC

Main Contractor - Spacemaker Abu Dhabi

The infrastructure utilities

work consisted of Drainage Network, involving the supply and installation of

uPVC pipes and fittings conforming to BSEN 1401-1, with pipe sizes up to 315mm,

and the installation of precast concrete manholes. For the Potable Water

Network, the works cover the supply and installation of uPVC pipes and fittings

as per BS3505, with sizes up to 200mm, along with pumps and a pressure vessel.

The Electrical Works scope includes the supply and installation of Main

Distribution Boards (MDBs) and Sub-Main Distribution Boards (SMDBs), as well as

associated power and earthing cable networks and earthing systems.

Client – EMAL

Project Location - Taweelah, Abu Dhabi

Main Contractor - Larsen and Toubro

The works consisted of

Pipeline Fabrication, Welding, and Installation comprising the supply,

fabrication, welding, installation, testing, and commissioning of Carbon Steel

(CS) piping up to DN600, Stainless Steel (SS) piping, and HDPE piping along

with necessary fittings, accessories, and painting works. These installations

support the potable water system, cooling water system, and pressurized air and

gas lines for both existing and new cast house facilities. Additionally, the

scope includes the relocation of HDPE pipelines for the potable water network

with pipe sizes up to DN300.

Project Location - Arzanah Island

Client – ZADCO

Contractor - ADMMI

The electromechanical works

involved the supply and installation of the fuel pipeline, GRP cable trays,

earthing system, and 13.8kV cable laying, along with testing and commissioning

of medium voltage (MV) cables.

Project

Location – Taweelah Abu Dhabi

Client

– EMAL

Main Contractor – Consolidated

Contracting Engineering

The works consisted of installation across various

networks: Storm water and drainage networks with RCC pipes up to DN2000 and

UPVC pipes up to DN600, including all necessary tie-ins and manhole

connections. Sanitary sewage networks involve installing UPVC pipes up to DN250

with connections to existing systems and manholes. Fire water networks cover

the installation of FRP pipes up to DN300, carbon steel pipes with welding,

wrapping, valves, and fittings. Potable water networks include installation of

HDPE pipes (SDR9) up to DN300 and fittings. Pressurized sanitary sewage systems

involve UPVC pipes and fittings up to DN200, including valves, tie-ins, and

manhole connections. Pumped storm water works include UPVC pipes and fittings

up to DN300 with valves and system tie-ins. Permeate service water systems

consist of SDR 9 HDPE pipes and fittings up to DN300 with valves and

accessories. Compressed air and natural gas networks involve carbon steel

piping with welding up to DN600. Lastly, utility road crossing duct works

include installation of UPVC road crossing ducts up to DN400 in size.

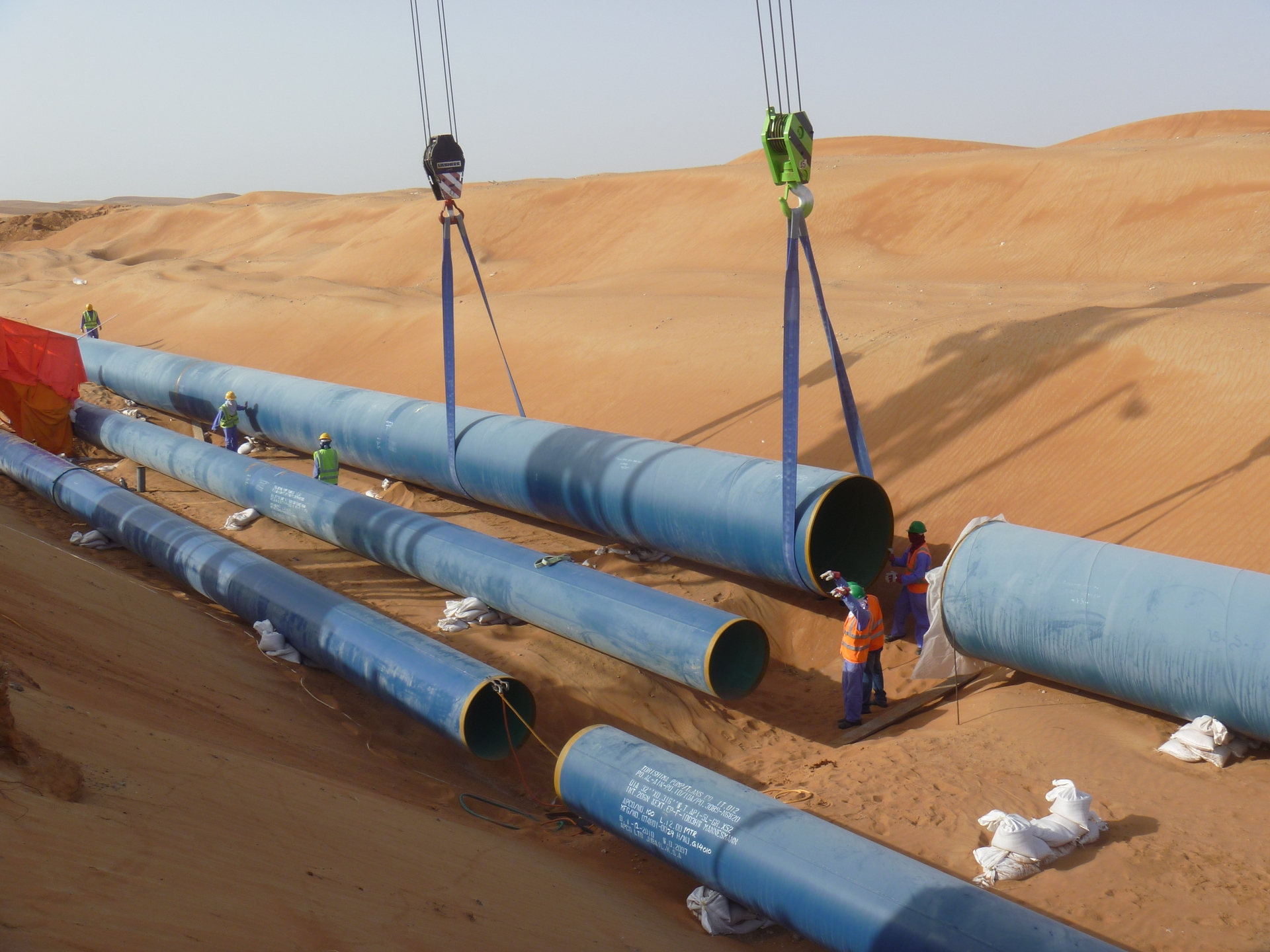

Project Location - Al

Ain

Client – TRANSCO

Main Contractor - Torishima

Pump Mfg. Co

The works consisted of

pipeline fabrication, welding, and installation for the potable water

distribution network. This includes fabrication, installation, and testing of

FBE-coated carbon steel pipes and fittings up to 2200mm in diameter (supplied

by the client). The work involves field welding of pipe joints, non-destructive

testing (NDT) of the welds, and holiday checks on the carbon steel pipes to

ensure coating integrity.

Project Location - Yas

Island, Abu Dhabi

Client – ALDAR

Main Contractor - Taisei

Corporation

The scope of

electromechanical works includes the Tunnel Ventilation System, encompassing

the supply, installation, testing, commissioning, and maintenance of 40 jet

fans, along with all necessary cabling, control panels, and SCADA interface for

system automation. The drainage network comprises the complete setup of three

storm water pumping stations, which includes 16 submersible pumps, stainless

steel pipework (up to DN350), valves, non-return valves (NRVs), level

instruments, and flow meters for automatic tunnel drainage operation. The

system also includes the connection of discharge lines to the existing drainage

system via oil interceptors and bar screens. The electrical works involve the

supply and installation of control panels for both the drainage and ventilation

systems, as well as all associated cable laying and termination. Additionally,

the instrumentation and SCADA interface scope includes the supply and

installation of ultrasonic level transmitters, float switches, limit switches

for valves, and integration of all instrumentation with the SCADA system.

Project Location - Al

Ain

Client – TRANSCO

Main Contractor - ASTRACO

Construction

The works consisted of

instrumentation and SCADA interface work along with electromechanical tasks.

This involves the supply, installation, testing, and commissioning of control

valves and an RTU shelter equipped with distribution boards (DB, SMDB, UPSDB)

and an A/C sequence panel for remote SCADA operation. Additionally, the work

covered the supply and installation of flow meters up to DN400 in size, along

with other associated instrumentation.

Project Location - Yas

Island, Abu Dhabi

Client – ALDAR

Contractor - ENVAC Middle

East

The works consisted of

pipeline fabrication, welding, and installation works includes the installation

of 5.89 km of 3LPE-coated mild steel pipelines for the automated waste

collection system on Yas Island. This involved fabrication, fit-up, and welding

activities. Additionally, a cathodic protection system is installed along 13.3

km, with exothermic welding of anodes at every 150 meters. Trench excavation

works cover 4.6 km for laying the MS refuse pipes, including bedding, sand

surrounding, compaction, warning tape installation, backfilling, and removal of

surplus excavated material off-site. The project also includes the construction

of 21 manholes with excavation works for inspection and maintenance of the

waste collection system.

Project Location – Dubai

Client - Nakheel

Main Contractor - Taisei

Corporation Dubai

The electromechanical works

consisted of both mechanical and electrical tasks, including the supply and

installation of cables and light fittings. The scope also includes the

installation of a penstock measuring 2800x1600mm, a 1600mm duckbill check

valve, GRP pipes and fittings up to 1800mm in diameter, along with the

associated civil works.

Project Location – Dubai

Client – Nakheel

Contractor - Taisei

Corporation

The works consisted of storm

water drainage network works include earthwork excavation for pipe laying,

including bedding, sand surrounding, warning tape installation, backfilling,

compaction, and removal of surplus material. The scope also covers the

installation of GRP pipes with diameters of 400mm, 1400mm, and 1600mm in

trenches, including GRP lamination joints.

Project Location - Yas Island, Abu Dhabi

Client – ALDAR

Contractor - Taisei Corporation

The works consisted of electrical

works for bridges BC-3, BC-4, BC-5, BC-7, and BC-8 include the supply and

installation of cables, junction boxes, and support systems. The scope covers

the installation of 108 light poles and bridge lights, 3,942 meters of 6-way

telephone ducts, and 1,902 meters of 6-way 22kV cable ducts (DN200).

Additionally, navigational lights, day markers, and control panels are supplied

and installed. The works also include the supply and laying of cables up to

16mm² over 6,050 meters and PVC conduits up to 100mm diameter totaling 3,170

meters.